BM300 is BROSIOMECCANICA's innovation in the world of quilting. We have applied our expertise in ultrasonic technology to the production and finishing of polyester microfibre and non-woven quilts and duvets.

BM300 is a fully automated machine using state-of-the-art rotary ultrasonic units for both the production of the quilted panel and its cutting and welding.

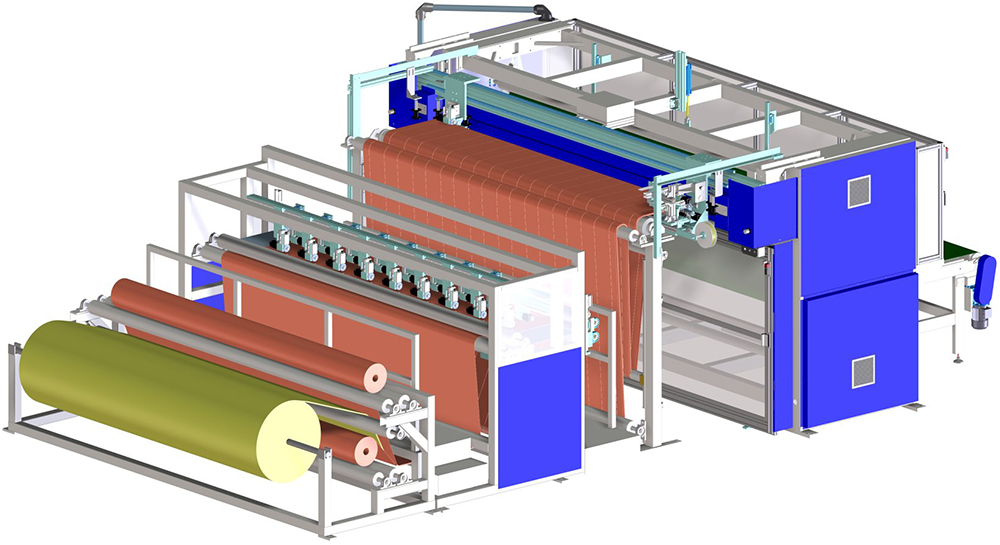

The machineconsists of an idle unwinding unit for the fabrics and wadding, a rotary ultrasonic quilting machine, which can mount up to 18 heads with a minimum distance of 175mm between each head, and an ultrasonic cutting/welding group, which performs the final cut and welding to size.

The polyester fibre wadding can also be fed directly from a carding line.

A mechanical dancer positioned between quilting and cutting/welding group ensures a continuous and independent production.

The production speed is connected to the thickness of the quilt over a maximum width of 3000mm.

Quilting patterns can be customised by moving the various heads or excluding them. The latest generation of rotating ultrasonic devices mounted on our line guarantee high production efficiency and strong and neat seams.