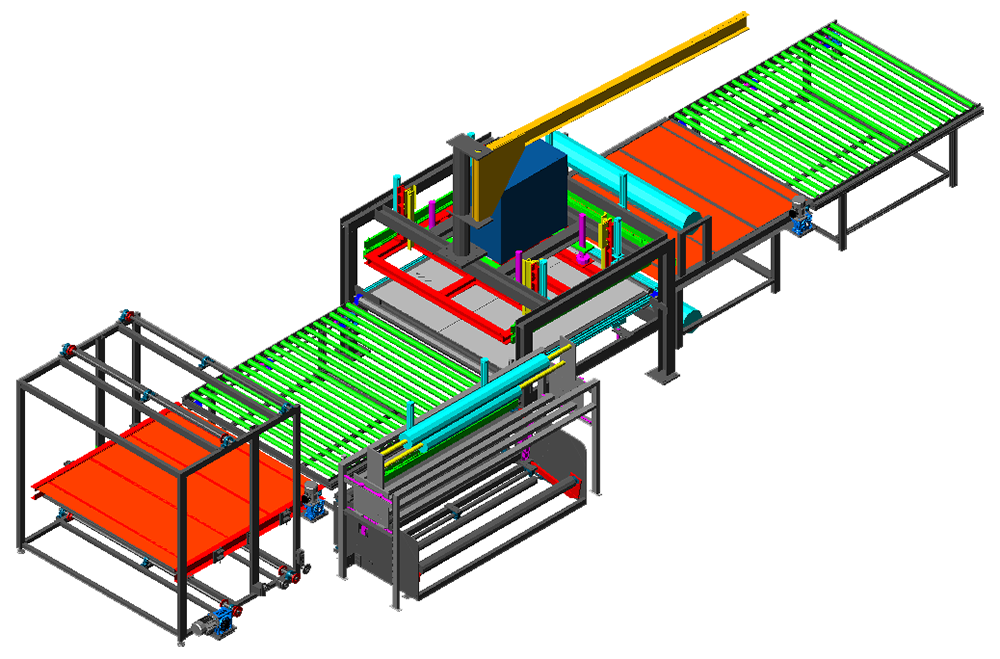

This machine has been developed to wrap and roll automatically mattresses in latex, memory, viscolatex and polyurethane in order to reduce their volume and make handling and transport easier. It is possible to adjust the diameter of the rolled mattress.

This machine has been developed to wrap and roll automatically mattresses in latex, memory, viscolatex and polyurethane in order to reduce their volume and make handling and transport easier. It is possible to adjust the diameter of the rolled mattress.The machine BM3023 give the possibility to select different work modalities:

SIMPLE PACK

The mattress is wrapped in a polyethylene bag manufactured started from two rolls of plastic film. The welding between the two plastic films are executed by welding hot bars.

PACKING WITH PRESSING

The mattress is wrapped in a polyethylene bag manufactured started from two rolls of plastic film. Before the laterals weldings are executed, the mattress is pressed by an hydraulic press to the defined force till 20ton

PACKING AND ROLLING

The mattress is wrapped and pressed in a polyethylene bag manufactured started from two rolls of plastic film. Than it is conveied to the rolling unit that rolls the mattress to the preset diameter. An unrolling unit fixed on the rolling unit, unroll an additional plastic lm that envelope the rolled mattress in order to protect it. After that the welding hot bar seals the mattress, the rolling-up unit opens to eject the rolled mattress.

As optional for the simple and packing with pressing work modalities, it is possible to add in exit of the machine a stacker unit, in order to stock the packed mattresses on trucks or pallets. The stacker unit is composed by a platform, with PVC belt, that moves automatically up and down to stack the mattresses one up the other